Table Of Content

Some of the factors you should consider while choosing a manufacturer for engineering design include manufacturing capabilities, quality of service, cost, material availability, and customer service. The requirements of the product design are discussed in detail and the expectations of the entire group are clearly understood. This includes high-level targets like product functionality, aesthetic requirements, budgetary constraints, material limitations, product quality, etc. Toyota’s Production System (TPS) is often cited as an example of Design Thinking applied to manufacturing.

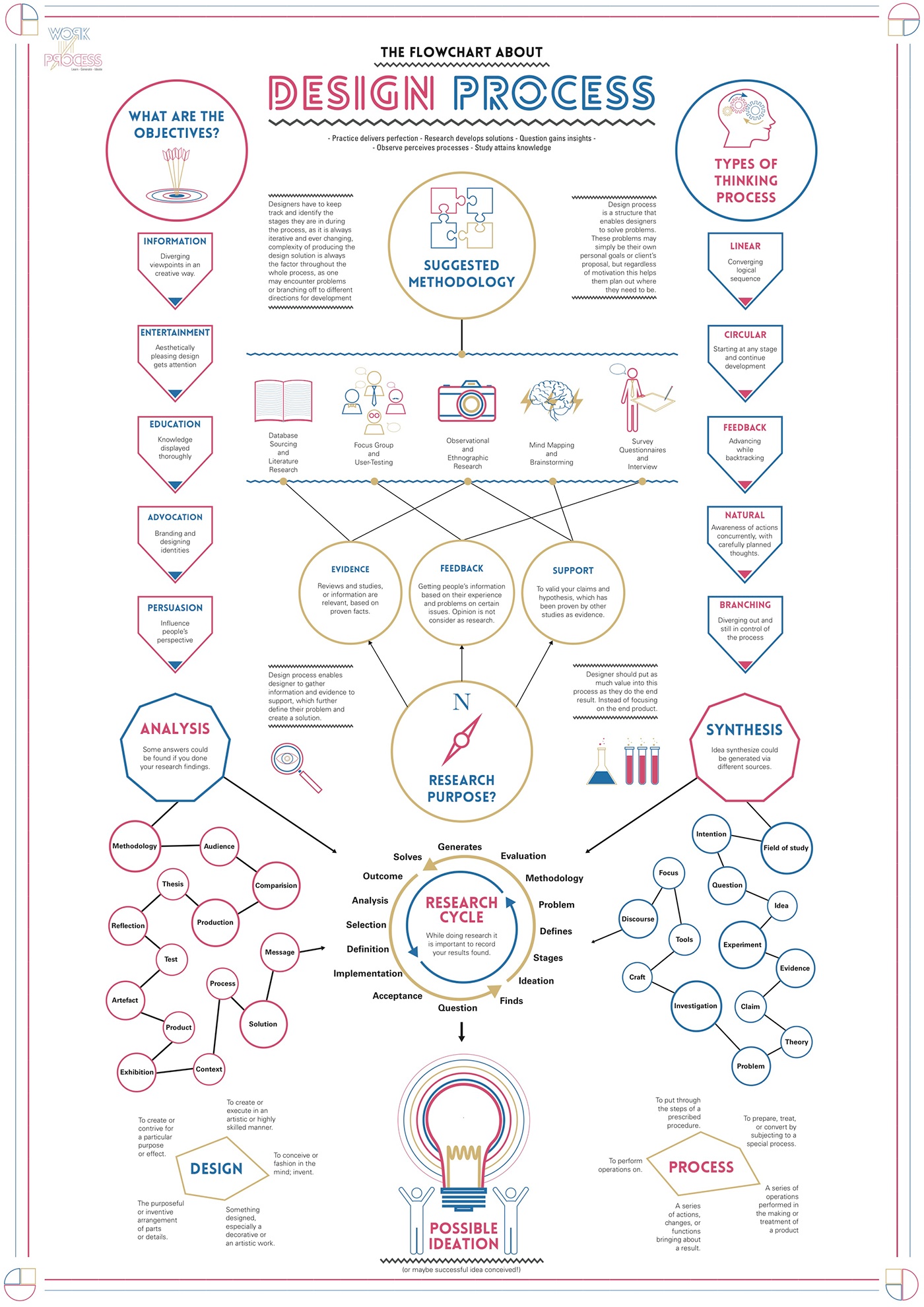

What is the design process? — and why every designer should know about it

Students engineer a working pair of shin guards for soccer or similar contact sport from everyday materials. Since many factors go into the design of a shin guard, students follow the engineering design process to create a prototype. Student teams design, build and test small-sized gliders to maximize flight distance and an aerodynamic ratio, applying their knowledge of fluid dynamics to its role in flight. Students experience the entire engineering design process, from brainstorming to CAD (or by hand) drafting, including resea... Students apply their knowledge of scale and geometry to design wearables that would help people in their daily lives, perhaps for medical reasons or convenience.

Scope — Feature Requirements and Content Requirements

This stage is focused on gaining a deep understanding of users’ needs, emotions, and behaviors in order to develop meaningful solutions. Next, you’ll focus on developing ideas quickly turned into prototypes and tested on real users. Inherent to the Design Thinking process is the early and frequent testing of your solutions; this way, you can gather feedback and make any necessary changes long before the product is developed. Students are asked to design a hockey stick for a school’s new sled hockey team. Using the engineering design process, students act as material engineers to create hockey sticks that have different interior structures using multiple materials that can withstand flexure testing.

What UX Deliverables Will You Produce as a Product Designer?

Goldberg and Benesh acknowledged that, given that this is a Nike project, the target demographic of the jerseys skews younger and to less experienced baseball fans. That said, they hope they’ve created something that will hit with all parts of the Mets fan base. Several other teams have gone with dark pants; the last six City Connect jerseys to be unveiled featured navy or black pants. The Mets toyed with that idea before landing back with more traditional white pants. Goldberg said they wanted to narrow in on that idea of connection and the experiences that bind everyone in New York together. “We actually had many designs with Queens across the chest,” Goldberg told The Athletic.

Step 4: Design

If you’d like to learn more about putting the Design Thinking process into context, you’ll find a comprehensive guide over on IDEO.com. Students are challenged to design and program Arduino-controlled robots that behave like simple versions of the automated guided vehicles engineers design for real-world applications. Using Arduino microcontroller boards, infrared (IR) sensors, servomotors, attachable wheels and plastic containers (...

Now is when you find out what functions well in your design work and what needs to be fixed. For example, a UX design process will work backward from the user experience. It’ll aim to address where users encounter problems with your products and what you can do to make them better. With the initial design concepts in hand, it’s time to test these with real users and gather feedback. Engage users in testing sessions where they interact with the prototype or concept.

What Is Empathy and Why Is It So Important in Design Thinking?

Kwong Von Glinow integrates model making into its design process - The Architect's Newspaper

Kwong Von Glinow integrates model making into its design process.

Posted: Wed, 01 Nov 2023 07:00:00 GMT [source]

This does not change anything about product utility, but it drastically decreases part rejections, cycle times, and material wastage. In this last section, we would like to touch upon the topic of engineering design and design for manufacturing. Both are highly interlinked fields that work together to make a product successful.

Student pairs design and construct small, wind-powered sail cars using limited quantities of drinking straws, masking tape, paper and beads. Teams compete to see which sail car travels the farthest when pushed by the wind (simulated by the use of an electric fan). Students design a way for mint plants to keep a constant moisture level for 72 hours.

Working as if they were engineers, students design and construct model solar sails made of aluminum foil to move cardboard tube satellites through “space” on a string. Working in teams, they follow the engineering design thinking steps—ask, research, imagine, plan, create, test, improve—to design an... Students learn the steps of the engineering design process (EDP) and how to use it ...

From here, you learn what implementations work and which one’s don’t, all leading to one solution. In the “Ideate” phase, the team synthesizes the insights gained to brainstorm a wide array of creative solutions. This stage encourages divergent thinking, where teams focus on quantity and variety of ideas over immediate practicality. The goal is to explore as many possibilities as possible without constraints.

This research forms the foundation of informed design decisions and reduces the risk of costly revisions later on. Effective UX design simplifies user interactions, and makes it easier for users to navigate and perform desired actions. Such interactions include making a purchase or signing up for a newsletter, which directly contributes to higher conversion rates. A well-designed, user-friendly interface increases user engagement and satisfaction.

No comments:

Post a Comment